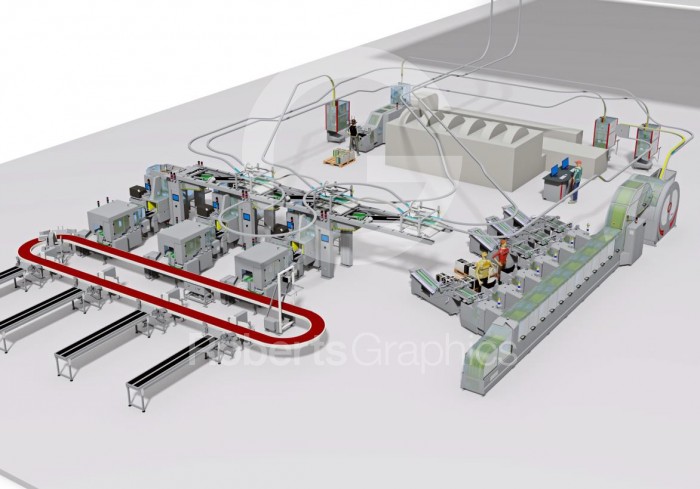

FERAG MAILROOM SYSTEM

Ferag EasySert Inserter, UTR Gripper conveyer, Multistack Stacker & PKT Bundle Dispatch System

Installation: April 2017 – October 2017

Operation Cessation: September 2018

Consisting of:

1. UTR Main Conveyor (UTR)

2. EasySert Inserting System

3. Compensated Stacking System

4. Navigator

5. PKT Bundle Dispatch System

6. Electrical Materials

Page2

1. UTR Main Conveyor (UTR)

The UTR conveyor is the basis of a mailroom, enabling to evacuate the press at its full speed (up to 90’000 copies per hour). The conveying system can be controlled via the Forwarding station. Check copies can be taken at the forwarding station or in the control room. Start-up waste, splice-, skewed and offset-copies are automatically recognized and released into a waste container at the Forwarding Station or at designated location in the conveyor line. Only correct copies are counted and conveyed to further processing systems.

1.1 Forwarding Station (AU2-MNK)

The forwarding station takes the copy stream directly from the folder delivery and transfers the copies to the universal conveyor.

The forwarding station mainly consists of:

self-supporting machine frame

double roller pressing device

side joggers for copy alignment

copy transfer device with pacer chain

main drive motor for universal conveyor

1:1 and 2:1 product gripping mode

integrated check copy extraction

conveyor control

offset frame for different formats

1.2 Conveyor Track Routing

For the flexible adaptation to individual building design requirements. Highest lifetime ensured due to use of a welded steel track construction, including:

All required long life steel tracks

Track length compensation

Welded construction

Three mechanical copy counter for gross, net, overflow.

The total length included for each line is as follows:

Line 1 = 180m

Line 2 = 155m

1.3 Conveyor Chain UTR-JV

Page3

For the conveying of each individual copy to further processing systems. Highest lifetime ensured due to use of maintenance free high grade steel chain, including:

All required high grade steel chain with strong ball-joint connection

Enforced swivel-action gripper which adapt to required copy position

Patented triggering mechanism for opening and closing of gripper

Long life smear free rubber rings

The total length included for each line is as follows:

Line 1 = 180m

Line 2 = 155m

1.4 Check Copy Extraction in Line KEE

For the controlled release of check copies into a Plexiglas chute, near the press control desk, including:

Release unit triggered by el. push button

Vacuum belt, frequency converter driven

Control unit

Plexiglas chute

1.5 Release Unit to the existing Buffer

For the controlled releasing of the copies to the buffer. The activation of the release unit happens by the buffers release control system, including:

Release unit

Interface to the existing buffer

1.6 Delivery Station AB2-C-OW-UTR

For the controlled releasing of any copies left in the UTRConveyor Line. If e.g. Overflow should occur copies will be properly released on the belt conveyor section for recovery, including:

Jam detector at exit to roller section

Roller section for manual pick-up

High accessibility for operation and service

2. EasySert Inserting System

Page4

For the inserting of pre-prints and supplements to the main jacket at speeds of up to 30’000 cph. High dependability is achieved due to the innovative production principle and the fact, that during the entire process copies are held in the UTR Conveyor line, thus do not require to be transferred. Well proven components such as JetFeeder, FlyStream and Universal Conveyor UTR are used to ensure production Reliability and safety on key functions. The JetFeeder can be set to run in a single, split-feeding and/or back-up mode. Its special design allows processing of a wide range of different products. Due to the modern operator interface the EasySert is easy to learn and very simple to operate.

2.1 Interface Belt System to connect the Ferag Copy Pacer

Stations with the existing Buffer System For the connection of the existing buffer system to the Ferag InterPacer copy pacer stations. The interface system is designed to turn around the copy stream in its orientation for further processing via the Ferag copy pacer stations into the Ferag MultiSertDrum inserter, including:

Interface to the existing buffer system

Bump-turn unit

Copy stream inverter belt

Drive and control system

2.2 Interpacer (ITP2-ESR)

For the gapless transfer of pre-prints, pre-inserted copies or supplements from the Multidisc or Printroll Unwinding System or a JetFeeder into the infeed conveyor chain of the EasySert Inserting System, including:

Drive and control system

Oscillating side jogger

Accurate laser copy counter

Dynamic height controlled copy buffer

Pick-up control for single copies

Infeed unit with buffer

Rotating star-wheel with 10 twin suction units

Transfer to the infeed chain

Connection for the multidisc tandem unwinding system

Page5

Connection for a JetFeeder hand feeder

Touch screen operator panel

2.3 JetFeeder

The mobile JetFeeder permits manual feeding of piled up main jackets into the working process. Due to its unique design it is possible to change formats within very short time.

Including:

Product feeding tray with guides

Fast central format adjustment

Remaining copy amount supervision

Double roller bar carpet to separate the products

Rotating star-wheel with suction units

Mobile unit

2.4 Universal Conveyor Line UTR-JV-KO

Basic element with 105 m UTR-Conveyor Line for conveying the copies between the processing units. Due to the overhead fixation good access to the individual units is ensured. Including:

Solid long life steel chain and track with UTR grippers

2.5 EasySert - inserting on the way

The main product enters the EasySert each held by its own UTR gripper. When running via the opening table the product will be opened by its overlap and held open by the spiral feeder. Thereafter the product remains open supported by the pocket and support plates. The inserts, pre-collected by the FlyStream, are fed into the main product as a package allowing processing a high range of pre-prints as well as commercial inserts, leaflets or even CD’s. During the whole process the main product always remains within in the UTR gripper mainly consisting of:

Overlap opening mechanism

Dual powered spiral feeders

Pocket plates to support the main product

Support plates

Page6

Turn around unit with opening/closing cams

Modern touch screen control system

Servo drives

2.6 FlyStream with six Infeed Positions

Collecting conveyor with gripper closing mechanism for a secure collection of various print products on the flow. Due to the Intelligent Repair Control “IRC” the manual handling of incomplete insert packages is reduced to a minimum. Only correctly inserted copies are being transferred to the further processing units downstream. As per the modular construction of the FlyStream, the system can easily be extended by

Additional feeder stations including:

2 Collating Module extendable in pairsbasis for 8 feeder stations

6 infeed looping with JetFeeder Interface

Collating conveyor with gripper closing mechanism

Drive and control system

2.7 JetFeeder

The mobile JetFeeder permits manual feeding of piled up preprints and supplements. Suitable over full format size range with fast and simple format change. High paginated products down to single sheets and CD’s can be processed. Large

pagination products can be fed in split-mode via two JetFeeders keeping full production speed,including:

Product feeding tray with guides

Fast central format adjustment

Remaining copy amount supervision

Double roller bar carpet to separate the products

Rotating star-wheel with suction units

Mobile unit

Page7

2.8 JobFeed Streamfeeder

The mobile JobFeed streamfeeder unit connects to any of the JetFeeder’s and enables the continuous manual supply of higher pagination products, including:

JetFeeder interface

Driven feeder chain

Autonomous drive

Speed control

2.9 TapeFix TPF

For the application of 2 adhesive tape stripes at the leading side of the collection/set delivered by the Fly Stream unit. The length of the stripes can be adjusted to match the suitable lengths for the relevant thickness of the collection/set. The stripes will be perforated in the middle for an easy separation. Tape Fix is a potential alternative for the direct mailing application as no cover or plastic bag will be required to ensure a proper distribution of the relevant collection/set including:

Interface to FlyStream collator

Tape dispenser(s)

Cutting/perforating unit

Touch screen operating panel

2.10 Delivery Station AB2-C-OW-UTR

For the controlled releasing of any copies left in the UTRConveyor Line. If e.g. Overflow should occur copies will be properly released on the belt conveyor section for recovery, including:

Jam detector at exit to roller section

Roller section for manual pick-up

High accessibility for operation and service

Page8

3 Compensated Stacking System

For the compensated stacking of programmed bundles according to the distribution data. The data can be downloaded from the Customer’s host computer to the Navigator via the intranet. Highest bundle quality even for difficult products because of gentle copy treatment. Low running costs because of consequential avoidance of compressed air consumption.

3.1 Infeed Belt for the MultiStack ZF-MTS2-2TR

For feeding of copies from the UTR conveyor to the MultiStack System, including:

Guided gripper opening via magnetic cam ENT-MTS2

Copy counter prior and after MultiStacks

Infeed belt for receiving copies from up to two gripper conveyors (positioned under one or the other conveyor)

Side alignment unit

Jam detector at infeed to pressing device

Pressing device

Central el. format adjustments via control button

Release control unit for communication with the Navigator control system

3.2 MultiStack MTS2

For the gentle formation of compensated bundles at high speed. Simultaneous movements allow lowest possible cycle time. Movements with servomotors for smooth bundle handling (soft start/stop), including:

All precise servo motor drive-technology

Accurate laser copy recognition

Adjustable air-suspended buckle stabilization

Jogger plate for continuous aligning of batches

Two fully independent dynamic intercept blade chains for guided lowering of batches

Lifting table for smooth transfer of batches to stacking cell with electronic dampening function

Revolving table with lateral stabiliser chains for bundle fixation while turning

Page9

Lateral guide chains for gentle bundle ejection

Optimised copy handling due to speed and pagination dependant servo motor movements

Central el. format adjustments via control button

Colour touch screen operator control panel

Scratch proof acryl glass covers with safety doors coupled to CE-emergency switch-off circuit

Interface to the Navigator control system

3.3 Top-Sheet Thermal Printer DBD-THM A4

For the reliable printing of the top-sheets at literally no maintenance efforts, including:

Top-sheet thermal printer Printronix

Processing of size DIN A4 labels

3.4 Top-Sheet Application System DBH2

For the in-line application of top-sheets to bundles during programmed production. The applicator is located immediately after the MultiStacks bundle exit for highest reliability,

Including:

Automatic paper application system

Processing of size DIN A4 labels

Interface to the Navigator control system

3.5 Bottom Wrapper KPZ-ECB-40

For applying of a covering paper under the bundles to protect them from soiling and mechanical effects prior to the strapping unit, including:

Drive and control system

Optical bundle recognition

Trimming knife

Page10

4. Navigator

Navigator is a highly versatile production programming and visualization system. It is unique the way it is operated. The Navigator features the revolutionary Flying Frame Technology, where an operator can intuitive browse through the various menus which are all up-dated in real time. At the forefront of this development are simplicity and the convenience of the user interface. The Navigator enables centralized operation on one screen per line. Thanks to the intuitive operator guidance, production with the Navigator can be started immediately, without extensive clarifications.

4.1 Navigator

The NaviSet, NaviRun, NaviQ and NaviSafe are all applications which run parallel and can be operated via the optional touch screen. The production is “Drag and Drop” operated. Routes, agents or loads can be simply selected by hand and put into production via a mouse click. Production progress is continuously updated and the production times of the Respective routes and agents are recorded. With the Online Editor, the number of copies per route, bundle parameters and many other attributes of the production data can be easily edited.

NaviSet:

Responsible for transferring and processing distribution data in the Navigator:

Automatically from the distribution system via Ferag string

Manually via Excel files or alternatively by manual entry

where there is no distribution system present

for external orders

NaviRun:

After selecting and confirming the production configuration, NaviRun monitors current events in the mailroom and provides real-time information to the operator:

Speed display

Visualise production progress (comparison of target / actual, and remaining quantity)

If needed, other actions can also be taken, such as:

Changing route sequences

Bundle-specific moving of routes

Reproducing bundles

Page11

NaviQ:

Real-time quality control, precise down to the single copy, in real-time or archived with the relevant reports. NaviQ offers an open interface for exporting data to Excel or CSV format:

Route report

shows the start and end times of the produced routes

Bundle report

can be monitored right through to the loading bay

production time in the MultiStack

topsheet applied Y/N

identification of missing bundles, e.g:

quality issues

fault on downstream machine

manually removed bundles

Production report

Visual display of production progress with target / actual comparison

Navi-Safe:

NaviSafe guarantees very high production reliability and easy data access:

Remote access via VPN connection

Integrated backup with redundant functionality

Open database for external access

4.2 NAVIGATOR Server NAV-SRV-OHW

The Navigator Server NAV-SRV-OHW hosts the central production database and allows the coordinated production for all connected NAVIGATORS. The NAV-SRV-OHW allows the

Allocation and re-allocation of production data from one line to another. It eliminates the risk of unwanted double production and does not require any mobile data carrier to shift production data from one line to another. All production relevant data are recorded on the Navigator Server and enable the provision of combined production reports over all lines, including:

1x NAV-SRV-OHW software package for the central server

Page12

The dedicated hardware for the central server of the NAVSRV-OHW is supplied by the purchaser in accordance with Ferag’s hardware specification). Together with NAV-SRV-OHW, the following items are supplied:

MDS-MHW (Mailroom Data Server) – hardware and software

IOH-MHW (Input/Output Host) – hardware and software

DS-PDO-OHW (Production Data Office) – software

FIW-VPN-MHW (Remote Access Firewall) – hard- and software

The above hardware is required to be installed near the NAVSRV-OHW hardware in an air conditioned environment. Details:

The Mailroom Data Server MDS-MHW is an operator less Microsoft Windows PC interface between the distribution system and the NAV-SRV, with the following roles:

Receiving production data from the distribution system. An FTP server is preinstalled to handle the data transmission.

Temporary storage and archiving of production data.

Enhancing the working data from the distribution system with format data for topsheet production.

Forwarding the prepared production data to the NAV-SRV.The I/O Host IOH-MHW is a Microsoft Windows PC, with the following functions:

FERAG remote maintenance

Central log server

MDS backup PC

Software management for the whole installation

Archiving of equipment documentation PDO is a Windows software package with the following

Functions:

Reading and editing existing production data.

Importing CSV files from Microsoft Excel and converting them to the FERAG production data format.

Producing distribution data with topsheets.

Page13

The Remote Access Firewall FIW-MHW is a remote access device (VPN 1 Edge) allowing a secure online access to the NAVIGATOR system from Ferag headquarters for the following purpose:

Initial installation and commissioning

Online support

Software updates

Includes the licence for the VPN 1 Edge for 2 years not included:

Hardware for the NAV-SRV-OHW, which has to be supplied by the purchaser in accordance with Ferag’s hardware specification

All passive network components, e.g. network connections and wiring between the NAV-SRV-OHW, MDS-MHW, IOHMHW, FIW-MHW and the three NAVIGATORS

Page14

5. PKT Bundle Dispatch System

The PKT Bundle Dispatch Conveying System is collecting the bundles coming from all Packaging Lines and is distributing them automatically to the assigned loading bay exit as per the information on their top-sheet. If a bundle should not have been identified, automatically it will be separated to a specially assigned exit. The PKT is communicating with the NAVIGATOR control system and is exchanging the relevant data about completed

And delivered bundles.

5.1 Bundle infeed module ETM

For the paced infeed of strapped bundles onto the PKT

Conveyor, including:

Drive and infeed pacer control

Driven infeed conveyor belt section

Hinged conveyor belt section

5.2 Bundle Dispatch System PKT

For transporting the bundles from the packaging lines to the required loader sections, including:

Plate conveyor chain and track (calculated length = 35m)

Tailor made support frames

Drive and control system

Track length compensation

2 turnaround units (one unit fitted with a roller belt section for no-read and overflow bundles)

5.3 Laser Scanner SCA-PKT

For the optical bar-code reading of bundles with a top sheet, including:

Barcode reading head

Interface to the despatch control system

Page15

5.4 Bundle Pusher Single

For the gentle pushing of the bundles to the determined loading bay exit, including:

Support frame

Pneumatic bundle pusher

Roller section to the telescopic truck loading belt

5.5 Loading Bay Display

Installed above the loading bay exit to display on two large LED Lines the name of the current route and the status of production. On the upper Line the current route name is mentioned and the lower line indicates effective and target amount of bundles for both standard and key-bundles separately. Once a route is completed the lower line will also show the name of the next route that is about to start,including:

Two 20 character lines LED display

5.6 Exit for Unidentified Bundles

For the extraction of unidentified bundles to a specially assigned exit, including:

Support frame

Pneumatic bundle pusher

Suitable for plastic film-wrapped bundles

Roller section

5.7 Bundle Dispatch System Control PKT2-ST

For the control of the bundle dispatch system and for the communication with the NAVIGATOR. Enables to receive bundle information from the NAVIGATOR and to confirm back the dispatched bundles, including:

PLC control

Page16

6. Electrical Materials

6.1 Mailroom Fuse Cabinet SIS2-65G

The circuit breaker concept provides electrical power protection for the mailroom components supplied by FERAG. The SIS mailroom fuse cabinet provides circuit breakers for the power

Distribution in the mailroom to the individual system parts of the Ferag system.

6.2 Service Notebook SVC-NBK

For maintaining all Ferag Mailroom System components electronically, including:

Complete notebook, charger

Software of most important components

Please leave us your details and we will get straight back to you or call us on: +44 (0)1924 890157 or drop us an email at: sales@rgl.uk