In today’s demanding printing environment, a flexible solution to booklet production is a must for all printers. Often there is a need to produce booklets from both digital presses and litho machines, or where covers have been coated or laminated.

The required print volume and quality will determine the appropriate printing method and in many cases the finished booklet has been printed on different print engines and thus needs to be merged.

Also, prints from a digital printers come pre-collated, whereas from an offset press they require sorting or collating. All this is a challenge for the finishing devices in order to keep a good workflow and maintain productivity.

The System 2000, with it’s versatile configuration and options can manage these challenges efficiently, to give a highly productive solution.

System 2000 key product features:

Air assist feeder unit

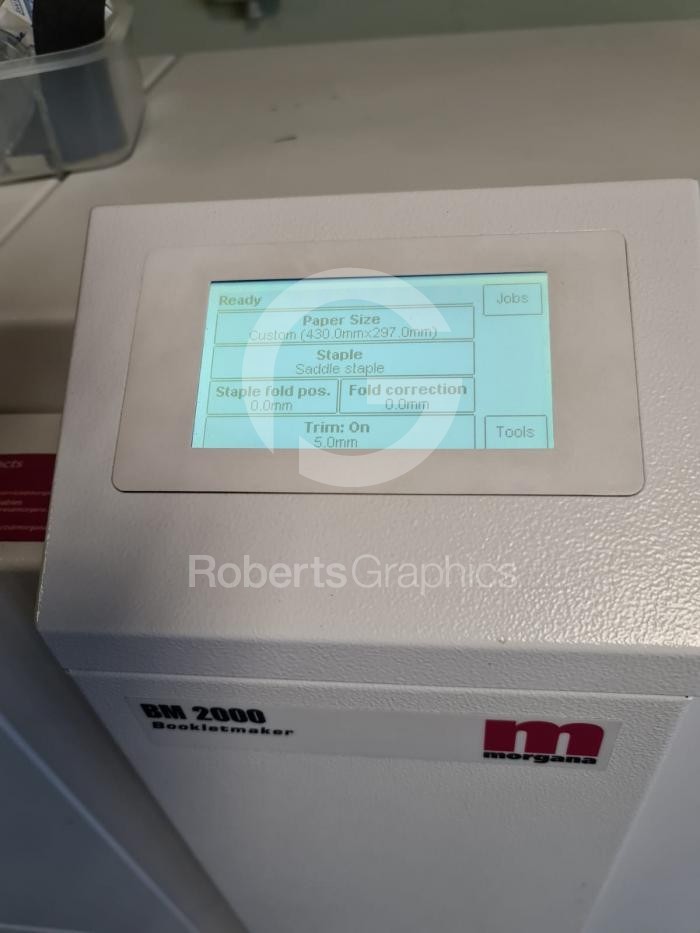

Large LCD programmable display

Up to 4000 sets per hour in collate mode

Feed pre-collated sets from digital devices

Convenient loading stapling head

30 x 80gsm sheets, booklets up to 120 pages

Up to 3000 books per hour

High quality front edge trimmer unit

Please leave us your details and we will get straight back to you or call us on: +44 (0)1924 890157 or drop us an email at: sales@rgl.uk